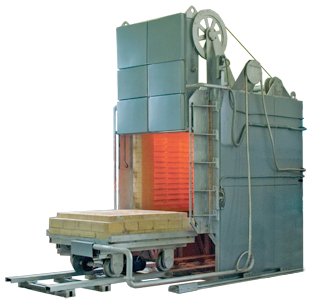

SNO, SNZ chamber furnaces

á

SNO, SNZ series chamber furnaces for heat treatment under air or protective atmosphereáat a temperature of up to 1250 °C.

SNO, SNZ series chamber furnaces for heat treatment under air or protective atmosphereáat a temperature of up to 1250 °C.

The furnacesáare used for annealing, baking,áquenching, normalizing and meltingáof metal products. They can be used as multi-purpose chamber furnaces for heat treatment of ceramics, porcelain and other materials.áThe furnaces can beáequipped byálift of wing door, pull-out hearth, fans and screens. Additionally the fire-proof bottom plates can be provided.

Working chambers of SNO and SNZ furnaces are made of modern high-performance fireproof materials.

The spiral heating elements areámounted on theáceramic tubes along the side walls.ááAdditional heating elementsácan be mounted on furnace hearth, back wall and cover.

Control system is based on a modern MBU series controllerá(made by MIUS). Control system continously diagnoses the power circuits, protecting the heating spirals from overheating, blowing-out and preventingáfrom concequences of breakage and short-circuits.

Theáfurnaces are certificated and complied with terms of reference 3442.009.24662585-04 (statement of complianceá#ROSS RU.╠Ď42.═00040 ţ˛ 26.08.2011).

á

Specificaton range*

| Operating temperature, °C | 150 - 1250 |

| Working area (W§D§H), mm | fromá200§500§200áto 3000§6000§3000 |

| Installed power, kW | up toá1000 |

| Temperature stability, °C | ±2 |

| Temperature deviation over working chamber, °C | up toá±5á |

| Atmosphere in working chamber | air, neutral gas |

á* Custom design according to customer requirements.

Key featuresá

- Development and manufacture of equipment in accordance with individual customer's requirements;

- Simple and reliable design;

- Ease of operation and maintenance;

- Advanced insulating materials;

- Dedicated power cabinet with the control system for optimal equipment positioning.

- Advanced features to control theáheat treatment process.

- PC-based centralized control system for monitoring and recording the heat treatment processes.

- Warranty and post warranty support.

Chamber furnace model rangeá

| Industrial chamber furnaces | |

| SNO-4.5.3/12,5-I1 | chamberá(W§D§H) 400§500§300, 1250°C, 30kW, heaters on the side walls |

| SNO-4.5.3/12,5-I2 | chamberá(W§D§H) 400§500§300, 1250°C, 30kW, add. heaters onáhearth andároof |

| SNO-5.7.4/12,5-I2 | chamberá(W§D§H) 500§700§400, 1250°C, 40kW, add. heaters onáhearth andároof |

| SNO-6.10.5/12,5-I2 | chamberá(W§D§H) 600§1000§500, 1250°C, 60kW, add. heaters onáhearth andároof |

| SNO-10.10.10/12,5-I2 | chamberá(W§D§H) 1000§1000§1000, 1250°C, 100kW, add. heaters onáhearth andároof |

| Industrial quenching chamber furnaces with bogie hearth | |

| SNOT-10.10.4/12 | chamberá(W§D§H) 1000§1000§400, 1200°C, 60kW, heaters on side walls, hearth and door,ábogie hearth isácombined with door |

| SNOT-10.10.10/12 | chamberá(W§D§H) 1000§1000§1000, 1200°C, 70kW, heaters on side walls, hearth and door |

| SNOT-10.10.10/12 | chamberá(W§D§H) 1000§1000§1000, 1200°C, 70kW, heaters on side walls, hearth and door, power-operated hearth and door |

| Industrial bogie hearth chamber furnacesáfor drawing, annealing, ageing | |

| SNOT-13,5.13,5.10/6 | chamberá(W§D§H) 1350§1350§1000, 600°C, 100kW, heaters on side walls, hearth and door, stainless steel fan and screens |

| SNOT-12.15.12/7,5 | chamberá(W§D§H) 1200§1500§1200, 750°C, 90kW, heaters on side walls, hearth and door, stainless steel fan and screens |

| Industrial chamber furnacesáfor heat treatmentáof aluminum andáalloys | |

| SNO-12.10.4/7 | chamberá(W§D§H) 1200§1000§400, 700°C, 50kW, wihout bogie hearth, stainless steel fan and screens, power-operatedádoor slides upward |

| SNO-6.10.5/7 | chamberá (W§D§H) 600§1000§500, 700°C, 50kW, wihout bogie hearth, stainless steel fan and screens, counterweighted lift-type door slides upward |

| SNO-12.15.12/7 | chamberá(W§D§H) 1200§1500§1200, 700°C, 80kW, power-operatedáhearth, stainless steel fan and screens,ápower-operatedádoor slides upward |

| SNOT-12.12.10/7 | chamberá(W§D§H) 1200§1200§1000, 700°C, 75kW, power-operatedáhearth, stainless steel fan and screens,ápower-operatedádoor slides sideward |

| SNO-13,5.13,5.10/7 | chamberá(W§D§H) 1350§1350§1000, 700°C, 80kW, power-operatedáhearth, stainless steel fan and screens,ápower-operatedádoor slides upward |